Guide – Energy Reduction

Minimising your carbon footprint whilst improving your work environment and reducing costs.

Minimising your carbon footprint whilst improving your work environment and reducing costs.

AES energy reduction services deliver a huge multitude of benefits for industrial and manufacturing companies. Our energy reduction services cover four main areas, all of which significantly reduce energy consumption.

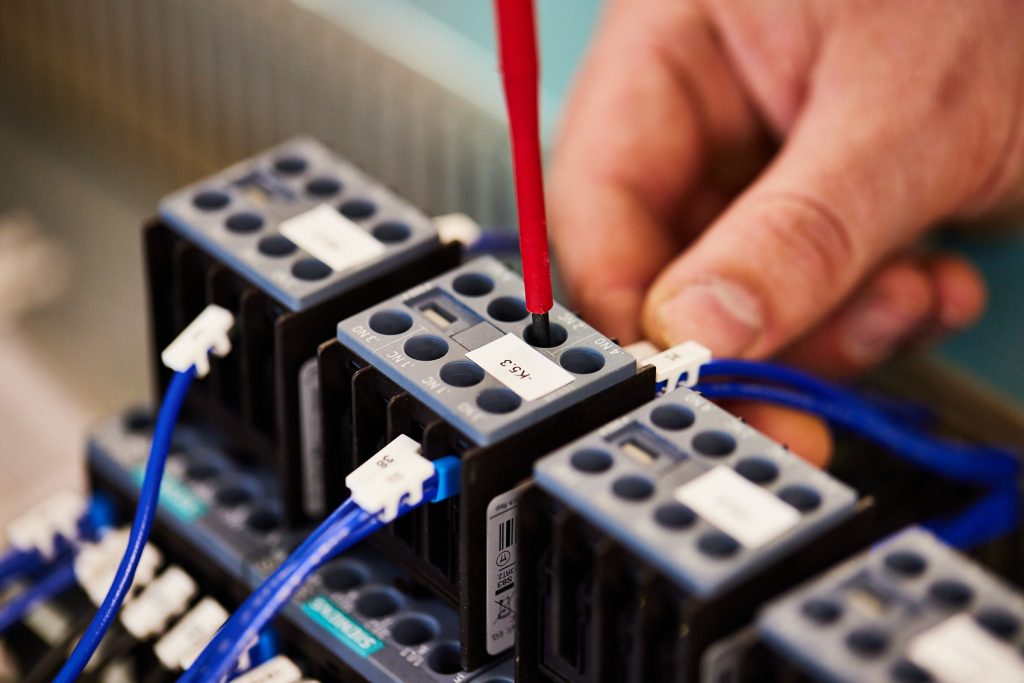

Guide – Electrical Contracting

Proactive electrical maintenance to minimise production downtime and eliminate inefficiencies

Read more

Guide – Safety Compliance

Ensuring workplaces are safe environments where all staff are protected

Read more

Guide – Energy Reduction

Minimising your carbon footprint whilst improving your work environment and reducing costs.

Read more

Guide – Control & Automation

Modernising production operations to maximise output efficiencies.

Read more

Have a question or need advice?

Call us today

or email and a member of our

team will get back to you