Charles F Stead

AES find the right energy reduction solution with 20.75% annual energy savings.

Case Study DownloadSector: Tannery

Service: Voltage Optimisation

The installation of voltage optimisation at Charles F Stead in Leeds was seamless and caused minimal disruption to business operations, but maximum benefit with impressive savings of 20.75% kWh energy reduction and a more efficient factory.

Case Study – Packing Hall Low Energy Lighting

Significantly enhanced staff working conditions with rapid ROI

Read more

Case Study – Energy Storage System

Energy storage system provides cost savings & eliminates production downtime

Read more

Case Study – Everbuild

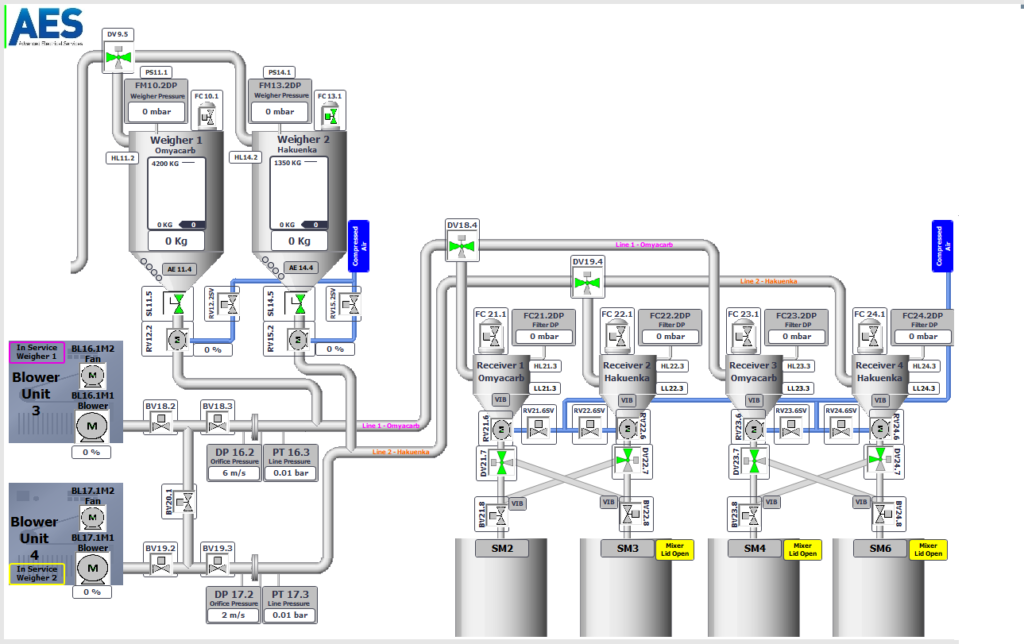

Elimination of manual handling delivers product consistency improvements

Read more

Case Study – Bibby Turboflex

AES low energy lighting project saves 48% in annual lighting running costs

Read more

Case Study – Kerry Foods

Operational efficiencies maximised with new equipment integration.

Read more

Case Study – Charles F Stead

AES find the right energy reduction solution with 20.75% annual energy savings.

Read more

Have a question or need advice?

Call us today

or email and a member of our

team will get back to you