Author: ian@opportunitymarketing.co.uk

Our guide to building energy management systems

Building energy management systems (BEMS) are systems that allow you to monitor, control, and optimise the energy used within your building. The phrase building energy management system (BEMS) is often used interchangeably with the phrase building management system (BMS), but there are some differences. A BEMS is focused on energy-related systems such as lighting, heating, […]

Read more

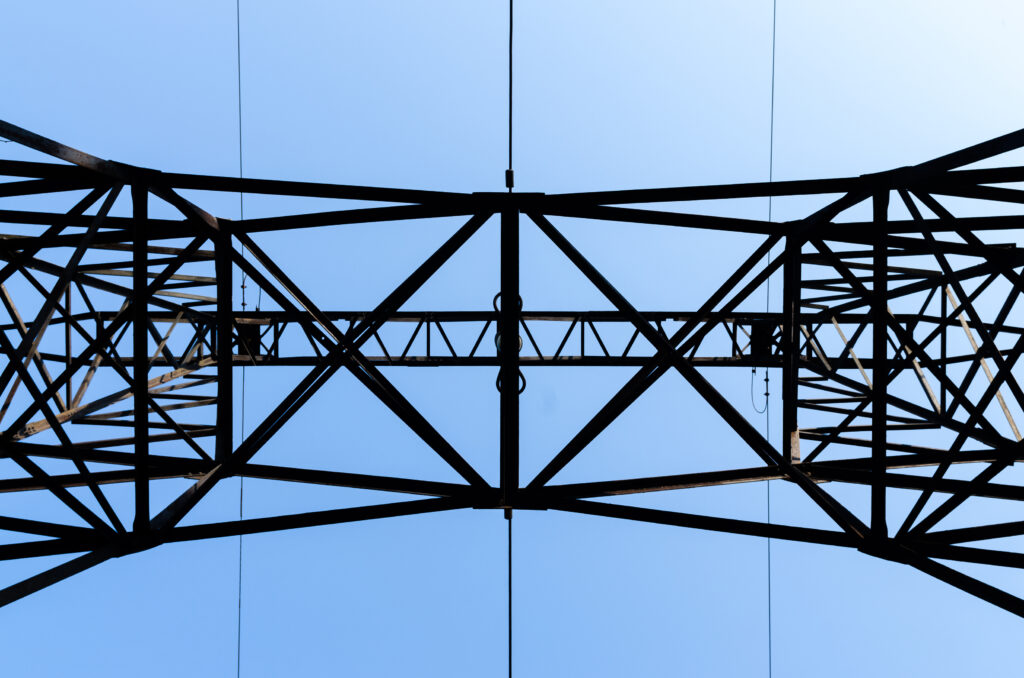

How far does power travel and what impact does distance have on performance

It’s easy to take our electricity supply for granted. We flick a switch and instantly have light or power. We don’t even think about it unless there’s an issue or an outage. But when there is an issue or outage, the impact can be significant. For manufacturers, even the smallest change in power can make […]

Read more

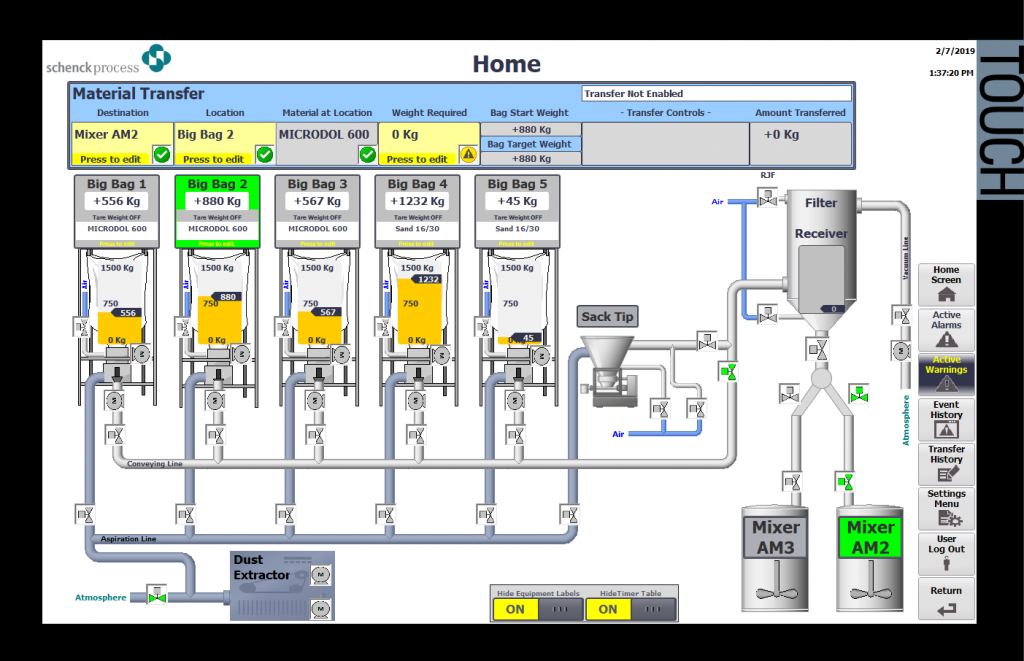

Why visibility of the production process is so important

Operational excellence, efficiency and quality are top priorities for almost every manufacturer worldwide. These things lead to improved productivity, happier customers and reduced waste – all of which result in increased profits. Visibility of the production process is the key to achieving these things. And manufacturers now have access to technology that can provide real-time […]

Read more

Will security lighting help to protect my staff?

Looking after the safety and well-being of employees should be a priority for any business. And while it’s not possible to mitigate every risk, there are measures you can take to improve their safety and security. One measure that is often overlooked is the installation of security lighting. When daylight disappears, visibility is reduced, increasing […]

Read more

Top 5 considerations when comparing electrical quotes

Budget is always a factor when you’re considering any type of upgrade, revamp, or maintenance work within your factory. But when it comes to electrical work, you have to consider more than just money. Don’t rush into accepting the cheapest electrical quotes without knowing exactly what you’re getting. Electrical work is not an area where […]

Read more

What is the role of companies in reducing our carbon footprint?

We should all be taking responsibility for protecting our planet and a big part of that is reducing our carbon footprint. But while it falls to all of us to do our bit, there is additional pressure on manufacturers, especially those with high carbon emissions. As an absolute minimum, these companies should ensure compliance with […]

Read more

How to identify when an electrical job is too big for you

You probably don’t want to call your electrical contractor every time a lightbulb needs replacing in the staff room – there are plenty of small electrical jobs you can handle in-house. But what about the larger jobs? How do you determine when an electrical job is too big for your onsite team? Here are some […]

Read more

Why changing your lighting can have a massive impact

One of the easiest and most cost-effective ways to improve a factory is to replace old lighting. It might not sound like a big deal, but changing your lighting can have a huge impact on everything from energy efficiency to productivity. Planned legislation will see fluorescent tubes completely removed from the market with other solutions […]

Read more

Why is it important to control voltage?

In the UK, commercial electricity suppliers are permitted to feed power from the grid into a network at 230v with a tolerance of -5/+10%. This means the supply may increase to 240v or reduce to 225v at any given time. On average, the supply runs as high as 242v. Most small work tools such as […]

Read more

Are manufacturers doing enough to reduce energy usage?

Climate change has been a hot topic for years now, and businesses are always under pressure to do their part. But are they doing enough to reduce energy usage? Are big businesses making big claims without taking action? Have those grand plans for reducing carbon emissions been left on a shelf to collect dust? Are […]

Read more

How often should I undertake an electrical audit?

All businesses have a responsibility to undertake a periodic electrical audit to ensure electrical safety. Part of this responsibility includes having an up-to-date commercial Periodic Inspection Report (PIR), also known as an Electrical Installation Condition Report (EICR). Commercial properties should get an EICR every five years or whenever there is a change of occupancy. Industrial […]

Read more

Why is certification so important?

Having the right certification in place isn’t just about ticking boxes. If you don’t have the right certification, you can face penalties, fines, and even prison time. That’s why it’s so important to understand your responsibilities. Electrical safety and compliance BS 7671 is the British Standard for “Requirements for Electrical Installations.” You may also hear […]

Read more

Top tips for lighting a warehouse

Lighting large spaces can be a challenge. Firstly, there are the safety aspects to consider – you need to ensure adequate lighting levels to reduce the risk of accidents and injuries. Then there are the practical elements – if your ceilings are over 20 feet, you need a high bay solution that can get the […]

Read more

Our guide to EV Charging at work

The EV revolution is well underway with over 700,000 electric vehicles on the road just in the UK. And with the government’s plan to ban sales of new petrol or diesel cars by 2035, the switch to EV shows no signs of slowing down. Combined with pressure on businesses to reduce their carbon footprint, it’s […]

Read more

10 signs that indicate you should be getting your wiring checked

When is the right time to get your factory wiring checked? What warning signs should you be on the lookout for? No manufacturer wants to disrupt production unless it’s absolutely vital. But equally, it’s not sensible to ignore warning signs and risk a minor issue turning into a major problem. 1. Frequent electrical surges […]

Read more

How to carry out vital electrical works without interrupting production

Unexpected downtime is never good, but if your power fails and you need to carry out electrical works, it’s unavoidable. This is why you need to be proactive with testing, inspecting, and maintaining electrical equipment and installations. But even planned downtime can cause disruptions to production which isn’t ideal when you’re on a tight schedule. […]

Read more

What actually is a power surge?

A power surge is a sudden, temporary increase in voltage that occurs in an electrical system, usually lasting only a fraction of a second. These surges can enter your factory through power lines and affect all electronic devices connected to your electrical system. Power surges can be caused by various factors, including: Electrical overload A […]

Read more

How to identify which equipment consumes the most power

If you’re worried about the impact rising energy costs are having on your bottom line, it makes sense to reduce energy consumption. But where do you start? How can you identify which equipment uses the most power and where the biggest inefficiencies are? Reducing energy use (and cost) is much easier if you understand where […]

Read more

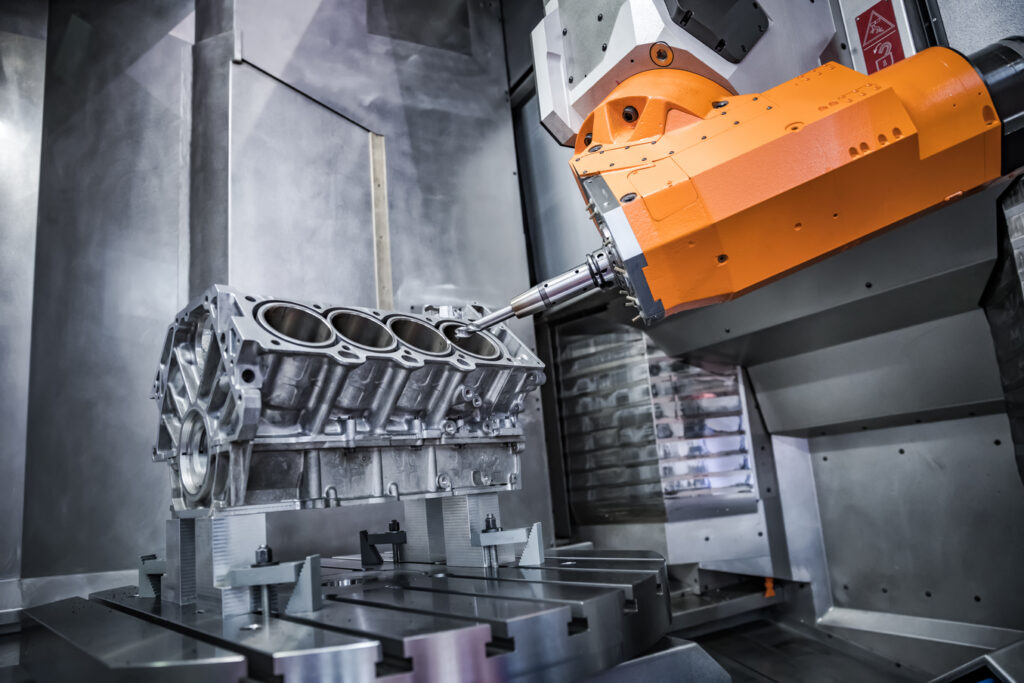

How control and automation can impact manufacturing efficiency

There’s no doubt that AI and robotics are changing the manufacturing world, making factories safer and more efficient and allowing production to be scaled up and down more easily. The key to unlocking these benefits is having effective control and automation systems. But what exactly does “control and automation” mean for manufacturers? Put simply; automation […]

Read more

What to take into account when designing a new factory

Planning a new factory is exciting, but there are lots of factors to consider. Poor planning can result in expensive problems later down the line, so it pays to invest time and money into getting it right. Factory design should be a collaborative effort involving engineers, architects, production managers, electrical contractors and other relevant stakeholders. […]

Read more

Reusing self-generated heat

One of the biggest drains on energy in manufacturing is the heat waste created by various machines and manufacturing processes (i.e. not reusing self-generated heat). Fortunately, there are ways to recover this heat and reuse it. And not only can this help reduce carbon emissions, but it can also lower energy costs. The first step […]

Read more

Top 5 tips for protecting staff

While manufacturing isn’t the most dangerous industry in the UK, it is still a high-risk environment compared to many sectors. And that’s why taking extra measures to protect your staff is crucial. The better protected your employees are, the lower the risk of accident, injury and illness, the higher your staff retention, and the lower […]

Read more

5 ways electrical contractors can improve your working environment

Most manufacturers rely heavily on electricity to power their factories and warehouses, which is why having reliable electrical contractors to call on should be a no-brainer. But the best electrical contractors aren’t just there to tick compliance boxes or fix things when they go wrong. A good electrical contractor should help you improve your business, […]

Read more

Lighting Control and how it can deliver ROI

You’re probably aware that switching your bulbs from CFL and halogen to LED can save you huge amounts of energy and significantly reduce costs. But switching your bulbs isn’t the only way to improve the energy efficiency of your lighting. Upgrading your lighting control systems can also deliver a return on investment. And in large […]

Read more

Electrical sparks – what to do when you see them

Electricity is all around us, and it’s all too easy to forget just how dangerous it can be. You might be hoping for sparks on a first date, but you certainly don’t want to see them in your factory. And sparks don’t just appear for no reason – they could signal a more significant electrical […]

Read more

How control and automation can improve equipment reliability

Unplanned machine downtime can delay production, increase waste, and impact profitability. That’s why having reliable equipment is so essential to manufacturers. One of the many benefits of control and automation is that good systems can improve equipment reliability, minimising unplanned downtime and reducing maintenance costs. What is control and automation in manufacturing? Control and automation […]

Read more

Why energy-efficient motors are worth investigating

Motors and drives are typically the biggest energy consumers on your production line and can account for around a quarter of your power usage. Given the rising energy costs and the focus on reducing carbon emissions, it makes sense to ensure they operate efficiently. So how do you know whether your motor is running effectively […]

Read more

Why proactive preventative maintenance is key to factory efficiency

When it comes to maintenance, many manufacturers opt for a “we’ll fix it when it breaks” approach, doing the bare minimum to stay compliant and operational, rather than taking a preventative maintenance stance. But being proactive with maintenance improves factory efficiency. And factory efficiency has a direct impact on productivity and profitability, so it’s not […]

Read more

Emergency lighting legislation explained

Everyone is familiar with the emergency lighting illuminated running man signs that sit above doors and exits in commercial properties. And we all know they aren’t there for decorative purposes – they’re there to guide people to safety in an emergency evacuation. But it’s not a case of simply sticking a few running man signs […]

Read more

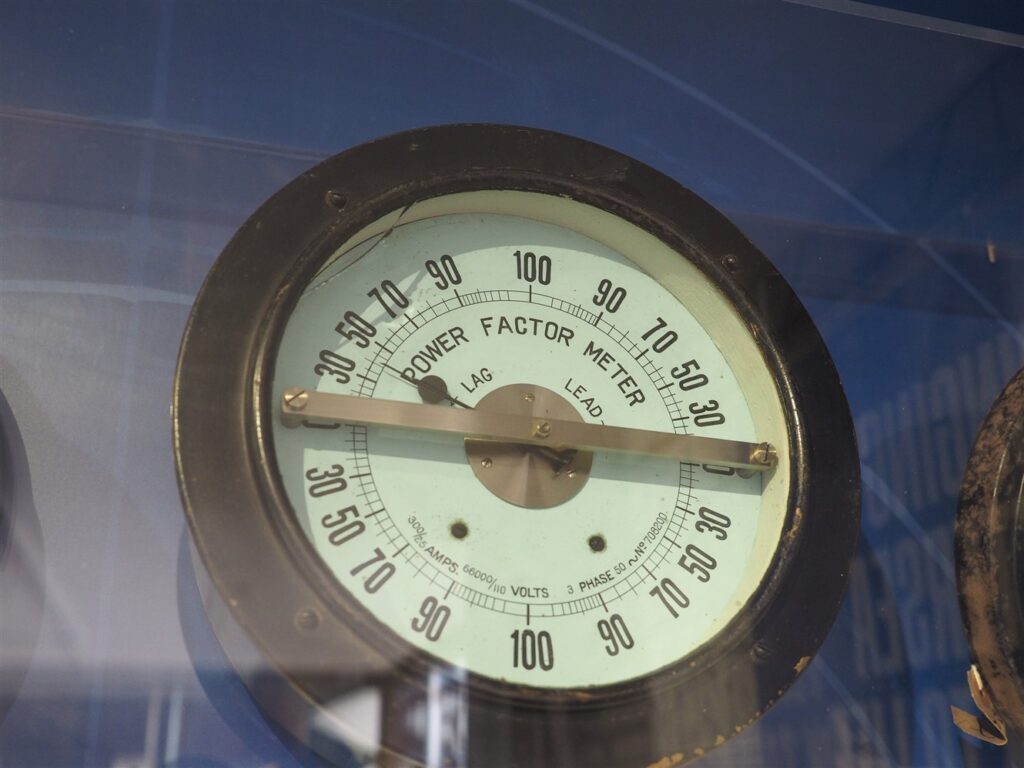

What is Power Factor Correction?

Power Factor Correction (PFC) is the process of improving power factor (and, therefore, power quality) by reducing the reactive power component of an AC circuit. Power factor measures how efficiently your electrical power is being used. It looks at the ratio between real power and reactive power to determine total power drawn by a single […]

Read more

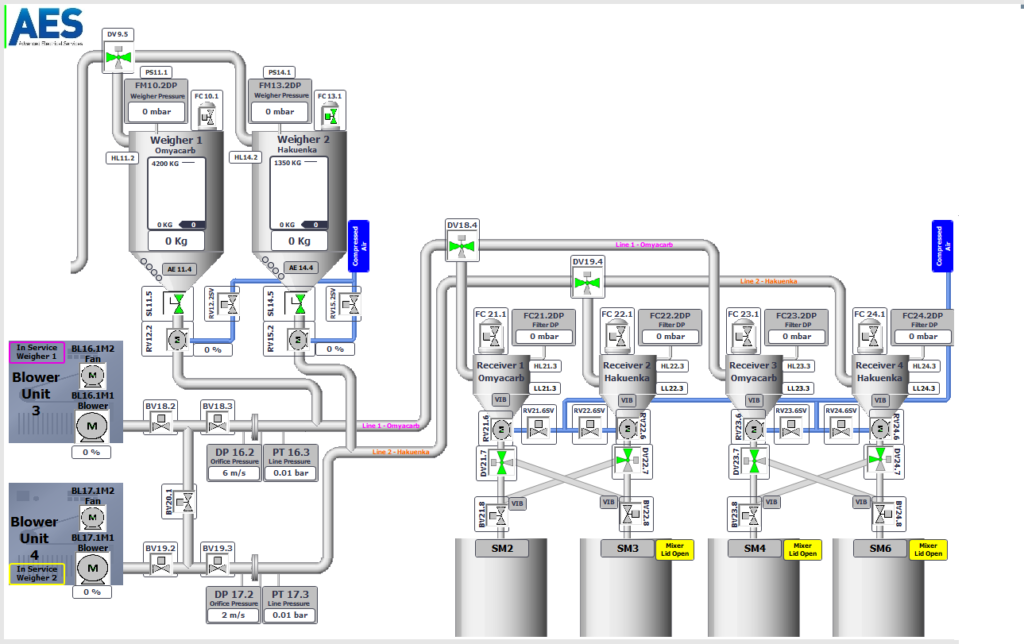

How Control & Automation can identify potential production problems early

As the saying goes – time is money. And this is certainly true in manufacturing, where an hour of lost production time can cause major problems. When everything is carefully scheduled – from the purchasing of raw materials right through to the transportation and delivery of the end product, you can’t afford lost production time. […]

Read more

LED, CFL and Halogen Lighting – what is the difference?

If you’re looking to upgrade your lighting, you’ll be hard pushed to find an electrical contractor recommending anything other than LED. LED lighting outperforms traditional lighting in terms of lifespan, efficiency, versatility, safety and eco-friendliness. Even if you pay a little more for the bulbs, you’ll save on operating costs, making LEDs the most cost-effective […]

Read more

What is classed as a hazardous area?

There are hazards in any workplace – even more so within a manufacturing facility. But while it’s important to identify and assess all risks, some areas are specifically classified as a hazardous area. And if your factory contains any hazardous areas, you have additional health and safety responsibilities under DSEAR, so it’s important you understand […]

Read more

Business continuity- are you prepared?

Most manufacturers rely on electricity to power their heating, lighting and ventilation, machinery and equipment. But what happens when machines break down, or the power goes out? How much would it cost your business if your production lines went down or you were without power for an hour, a day, or a week? We can’t […]

Read more

British manufacturing: a time to thrive

It’s been a rocky few years for the UK, with Brexit, the pandemic, energy price increases, and changes in government leadership all taking their toll on the economy. But despite many businesses facing turmoil, it’s not doom and gloom for everyone. British manufacturing is seeing some exciting results and is set to play a key […]

Read more

Case Study – Packing Hall Low Energy Lighting

Significantly enhanced staff working conditions with rapid ROI

Read more

Case Study – Energy Storage System

Energy storage system provides cost savings & eliminates production downtime

Read more

Case Study – Everbuild

Elimination of manual handling delivers product consistency improvements

Read more

Why energy storage solutions could save businesses thousands

Energy storage solutions are not new. They have been around a while. But with rapidly advancing technology, rapidly increasing energy costs and initial investment outlay costs decreasing, battery energy storage systems are the latest technology that most reasonably sized commercial operations should be considering. The UK Government estimates that battery storage systems could save the […]

Read more

How a factory audit can identify potential savings

In most manufacturing facilities, the top three operating expenses are labour, materials and energy, with energy often coming out as the highest cost. A free energy reduction audit from AES will identify potential energy savings across your factory, helping you minimise your carbon footprint whilst improving your work environment and reducing costs. What are the […]

Read more

Energy Saving Tips – from “marginal gains” to “game changers”

Energy costs are increasing, and there’s no indication when (if ever) prices will come back down. Not surprisingly, businesses across every sector are looking for ways to minimise energy use, reduce waste, and save on cost. The good news is there are plenty of opportunities to improve energy efficiency, no matter how large or small […]

Read more

How to create a safe working environment

Health and safety should be a priority for any business, not just because of legal obligations but for moral reasons too. Your people are your most important asset, so you should want to keep them safe, minimising the risk of accidents, injuries or infection. But how do you ensure a safe working environment, especially in […]

Read more

Top tips to lighting a factory

Manufacturing plants need adequate lighting – if your teams can’t see, they can’t work. But lighting big spaces can be a challenge, not to mention a huge investment. With health and safety, energy efficiency and cost all playing a part, it pays to plan. In this article, we’re sharing our top tips to lighting a […]

Read more

5 Key questions in choosing an electrical contractor

If you’re planning a major electrical installation or upgrade at your commercial premises, you’ll need an electrical contractor. But a quick search on the internet will show you thousands of electrical contractors, possibly hundreds just in your local area. So how do you know which is right for your business? This article looks at the […]

Read more

What can we do to create more energy-efficient buildings?

With climate change a growing concern and energy costs soaring, the need to create more energy-efficient buildings is clear. Individuals and companies are doing their bit to reduce consumption wherever they can. But if we really want to make a difference, we need to think beyond just turning off a few lights and boiling the […]

Read more

What electrical regulations do I need to know about?

We all know health and safety at work is a big deal. Business owners want a clean sheet on safety for many reasons, not least to keep a happy and healthy workforce operating at its best. In the past fifty years, much has been done to create procedures to support workplace health and safety. From […]

Read more

How to review which production processes can be automated

Smart manufacturing has arrived, and many manufacturing businesses are already well on their way to fully automated systems, significantly reducing their assembly time and costs. Cutting-edge machinery, and technical innovation such as AI, are fast becoming common practice and manufacturers who don’t invest are likely to get left behind. But major upgrades can mean considerable […]

Read more

5 most common electrical problems in factories

Manufacturers rely heavily on electricity, often grinding to a halt if electrical problems occurs. What’s more, serious electrical faults can trigger a fire or explosion, leading to injuries or, much worse, fatalities. As a plant or production manager, you don’t need to understand how to fix your factory’s electrical faults yourself – that’s our job. […]

Read more

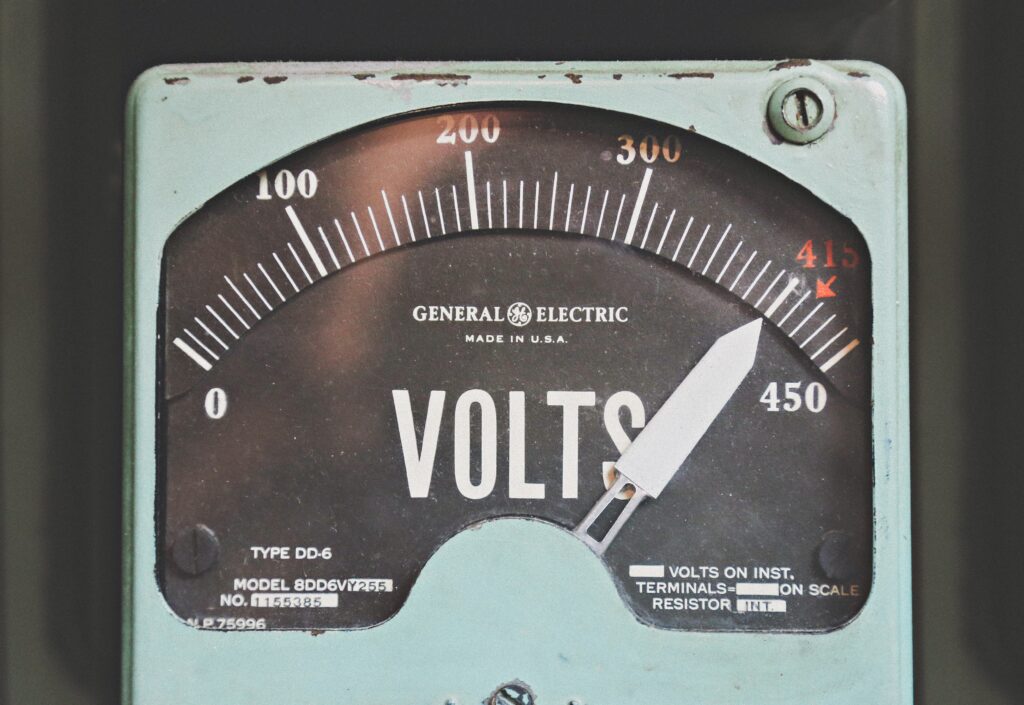

Voltage optimisation explained

Recent increases in energy costs mean power consumption has become one of the biggest concerns for companies in the manufacturing sector. Streamlining the production process to remove unnecessary and costly consumption points is a good exercise. But one of the easiest and most effective ways to manage energy consumption and reduce costs is voltage optimisation. […]

Read more

Key factors when planning a factory extension

Customer demand can peak and trough, but if demand for your products is constantly rising, it could be time to expand. However, upsizing a factory is not straightforward. There are multiple components to think about before you begin to extend, and you might even find that relocation is a more viable option (although this is […]

Read more

How control & automation can protect your staff and put you in control

While many modern machines are created with automation in mind, countless factories still run on old, inefficient technology. But without efficient equipment, systems and processes, your costs become unpredictable. If you’re still using outdated technology in your manufacturing plant, you’re likely paying over the odds for staffing, machinery and utilities. And old equipment isn’t just […]

Read more

Will modern equipment reduce commercial energy costs

As a sector, manufacturing is responsible for using millions of megawatts of energy daily, long since a concern for anyone managing production and even more so in a period when commercial energy costs are heading upwards. With energy prices rising at an unprecedented rate, it has never been more critical to consider ways to streamline […]

Read more

What are the DSEAR regulations surrounding hazardous areas?

There are many hazards in the workplace, particularly within the manufacturing sector. Consequently, a fundamental for any manufacturing business is workplace safety. Indeed, with the number of opportunities for accidents at their greatest in this type of environment – thanks to the machinery and materials used – it’s imperative you have robust procedures to protect […]

Read more

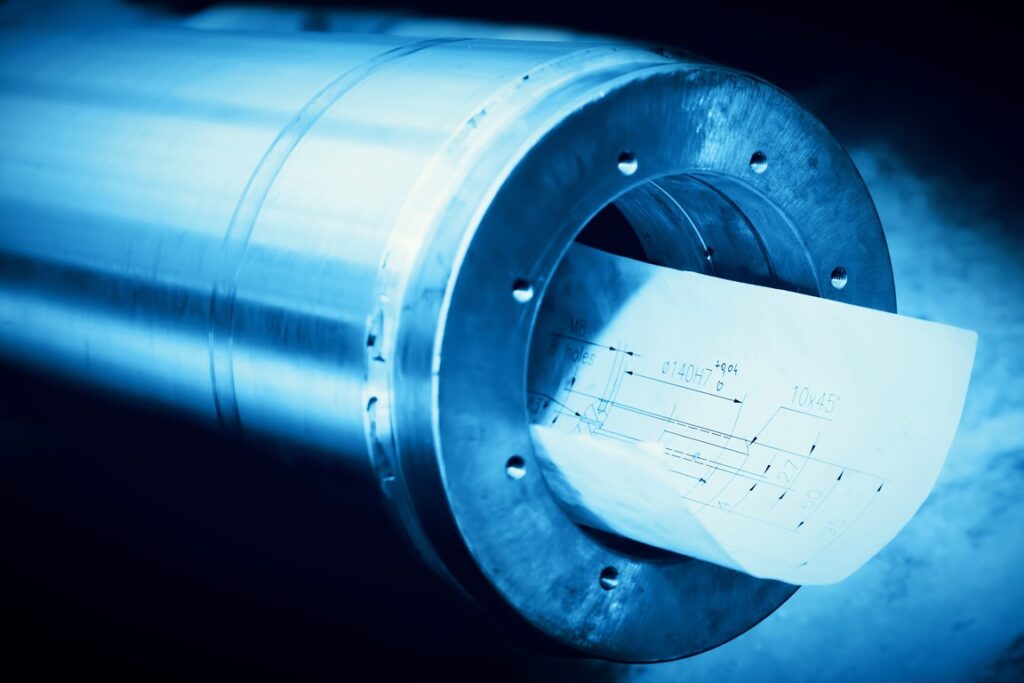

Understanding the design process in new factory installations

The key to achieving an efficient production plant lies in its design. Whether you’re creating a brand new facility or simply assessing your current installations to make improvements, getting the design spot-on is essential to the production output. In this article, we’re looking at manufacturing design in more depth – asking questions about the DFM […]

Read more

LED lighting – what’s all the fuss?

Energy prices are a huge concern for everyone right now, so it’s not surprising that most businesses are looking for ways to save. But cost shouldn’t be the only reason to adopt energy-efficient ways of working. Making your factory more efficient reduces your carbon footprint as well as your bills. Rapid advancements in lighting technology […]

Read more

How Variable Speed Drives can make an impact

The manufacturing sector seldom sleeps. Across the world, production facilities operate around the clock to meet their customers’ demands. Anyone overseeing a manufacturing plant knows there are three key components to its operational success: • Using machinery that is fit for purpose • Conducting regular planned maintenance to keep machinery in good condition • Implementing […]

Read more

Top 5 tips for minimising production downtime

Unplanned downtime – every production line will experience it, but none will welcome it. It’s among the biggest concerns for anyone running a manufacturing plant, capable of causing havoc in seconds and resulting in severe financial losses. Of course, not all production downtime is bad. If you’re upgrading a major system or implementing a brand […]

Read more

Why machine risk assessments are business critical

While health and safety should be a priority for all commercial businesses, the manufacturing industry has additional considerations. Plant machinery and electrical equipment must be installed and operated safely. If a machine is modified, reconfigured, or interlinked on a production line, this can affect the integrity. And it’s the company operating the machine that is […]

Read more

Top Tips for identifying potential electrical hazards

No business owner wants to deal with a workplace accident, but unfortunately, they are all too common, with machinery or equipment often the root cause. Where electricity is present, there’s an added risk, and the consequences of ignoring hazard warning signs can be fatal. There are several steps a business can take to prevent accidents in […]

Read more

A Carbon Free Energy Vision (and what we can all do to contribute)

Fossil fuels have been used as fuel for many centuries and are still the biggest energy source for generating electricity. In fact, around 75% of electricity in the UK still comes from power plants that rely on fossil fuels. Unfortunately, coal and oil are not renewable energy sources, meaning there is a finite amount available. […]

Read more

How automation can make a dramatic impact in manufacturing

With AI and robotics advancing at an astounding rate, there aren’t many parts of a manufacturing process that can’t now be automated at some level. In this article, we’re looking at how automation can dramatically impact the productivity and profitability of manufacturers in any sector. What can be automated? It’s easy to think of […]

Read more

What is CompEx & ATEX?

If you work within the manufacturing industry, you might well be familiar with the terms ATEX and CompEx, but do you know how they relate to your business? In this short article, we’re explaining exactly what the terms mean and why they should matter to you and your teams. What is ATEX? ATEX derives from […]

Read more

The Future of Energy Efficient Factories

There’s no denying that in recent years there has been a substantial focus on carbon emissions. The growing pressure on governments to decarbonise energy systems is filtering down to manufacturers who are having to seriously evaluate their impact on the environment. Leading companies are proactively implementing initiatives to reduce their carbon emissions. Some companies are […]

Read more